The industrial sector has been continuously evolving with the rise of automation, and the future of autonomous systems is set to revolutionize the industry even further. Autonomous systems, driven by Artificial Intelligence (AI), Machine Learning (ML), and advanced sensor technologies, are enabling machines and processes to operate without human intervention. These systems promise to increase efficiency, reduce operational costs, and improve safety across industries. For an in-depth look at the future of automation, explore The Complete Guide to Automated Controls for Industrial and Commercial Applications.

In this blog, we’ll examine how autonomous systems are transforming industrial automation and what we can expect in the future.

What Are Autonomous Systems in Industrial Automation?

Autonomous systems refer to machines and processes that can operate independently without the need for manual control. These systems are capable of making decisions based on real-time data and pre-programmed algorithms, allowing them to perform tasks such as monitoring equipment, adjusting production processes, and even repairing themselves in some cases.

In industrial settings, autonomous systems use advanced AI and ML technologies to continuously learn from data, adapt to new conditions, and optimize processes. These systems not only improve operational efficiency but also reduce the risk of human error, leading to safer and more reliable operations.

Key Technologies Driving Autonomous Systems

Several key technologies are at the forefront of autonomous systems in industrial automation:

- Artificial Intelligence (AI): AI enables autonomous systems to analyze vast amounts of data and make decisions based on real-time inputs. AI-powered systems can predict equipment failures, optimize production processes, and reduce energy consumption.

- Machine Learning (ML): ML algorithms allow autonomous systems to learn from historical data and improve their performance over time. In manufacturing, ML can identify patterns in production data to optimize workflows and reduce waste.

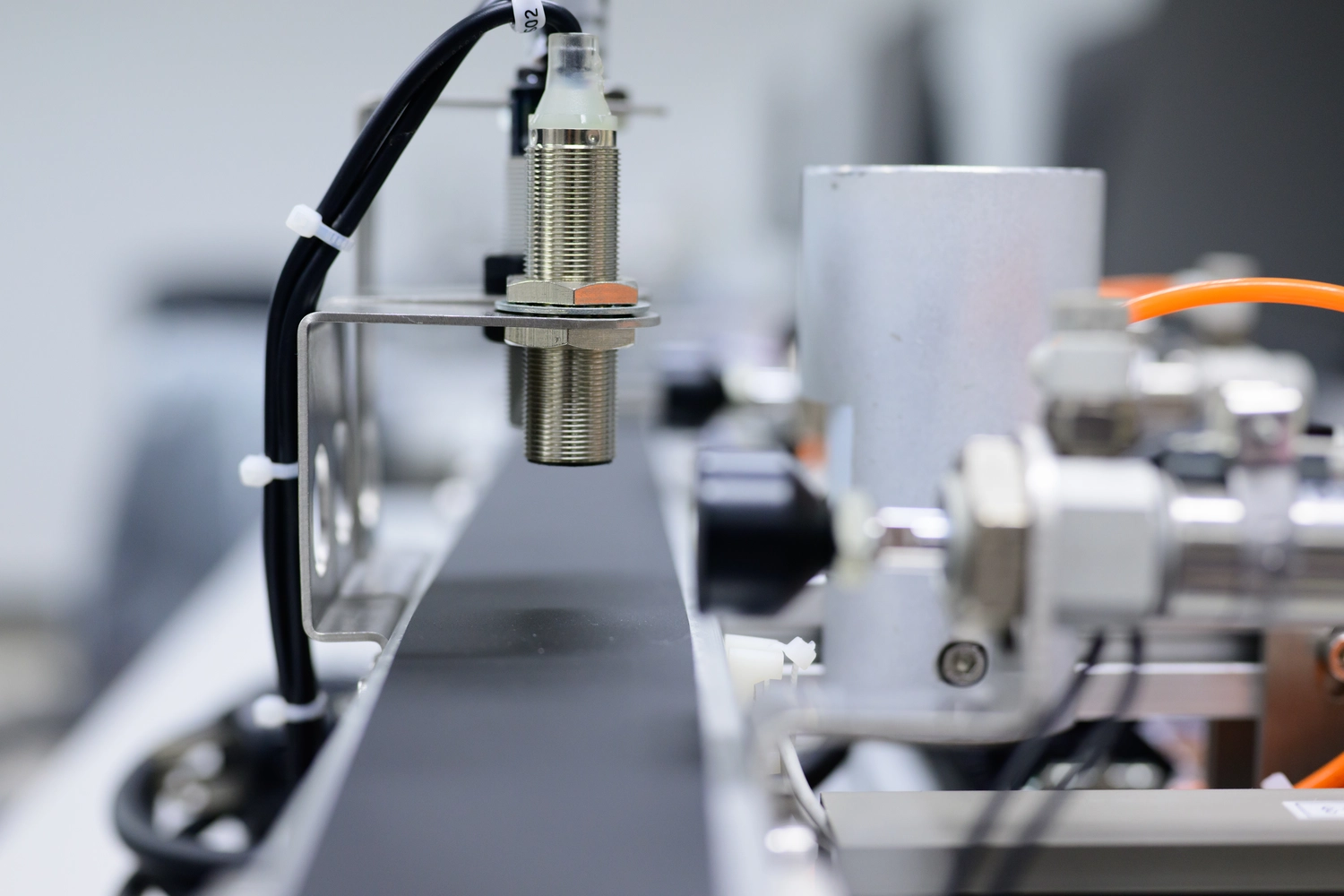

- Sensor Technologies: Advanced sensors provide real-time data on temperature, pressure, vibration, and other variables, enabling autonomous systems to monitor equipment and processes without human intervention.

These technologies work together to create a fully integrated, intelligent automation ecosystem that allows machines to operate autonomously, improving both efficiency and safety.

Autonomous Robots in Industrial Settings

One of the most significant developments in autonomous systems is the use of autonomous robots in industrial settings. These robots can perform tasks such as material handling, assembly, and quality control without human oversight. For example, autonomous robots are widely used in warehouses to transport goods, reducing the need for manual labor and improving efficiency.

In manufacturing, collaborative robots (cobots) are used to work alongside human operators, performing repetitive or dangerous tasks. Cobots are designed to be flexible and easy to program, allowing them to adapt to different tasks and processes quickly. This versatility makes them a valuable asset for manufacturers looking to increase productivity and reduce labor costs.

The Impact of Autonomous Systems on Efficiency

One of the most significant benefits of autonomous systems is their ability to improve efficiency. By automating repetitive and time-consuming tasks, autonomous systems free up human workers to focus on more strategic activities. Additionally, autonomous systems can operate 24/7, increasing production output and reducing downtime.

For example, in the mining industry, autonomous vehicles are used to transport materials from mines to processing plants. These vehicles can navigate challenging terrains without human intervention, improving safety and efficiency. Similarly, in the logistics industry, autonomous drones are used to deliver packages, reducing delivery times and improving customer satisfaction.

Enhancing Safety with Autonomous Systems

Safety is a top priority in industrial settings, and autonomous systems play a critical role in improving workplace safety. Autonomous systems can monitor hazardous environments and equipment in real-time, detecting potential risks and taking corrective action to prevent accidents.

For example, in oil and gas refineries, autonomous drones are used to inspect pipelines and detect leaks. These drones can access hard-to-reach areas and provide real-time data on the condition of the infrastructure, reducing the need for workers to enter dangerous environments.

By reducing the need for human workers to perform hazardous tasks, autonomous systems help prevent workplace injuries and improve overall safety.

The Role of AI in Autonomous Maintenance

One of the most exciting applications of AI in autonomous systems is its ability to perform predictive maintenance. AI algorithms analyze real-time data from sensors to predict when equipment is likely to fail, allowing businesses to perform maintenance before a breakdown occurs.

In some cases, autonomous systems can even perform maintenance tasks themselves. For example, self-repairing robots are being developed to identify and fix minor issues in machinery without human intervention. This level of autonomy reduces downtime, extends the lifespan of equipment, and lowers maintenance costs.

The Future of Autonomous Systems in Industrial Automation

The future of autonomous systems in industrial automation is full of possibilities. As AI, ML, and robotics technologies continue to evolve, autonomous systems will become even more capable and intelligent. We can expect to see more industries adopting autonomous systems to improve efficiency, reduce costs, and enhance safety.

One of the most promising areas for future development is the integration of autonomous systems with smart factories. Smart factories use IoT devices, AI, and automated control systems to create fully connected, data-driven production environments. In smart factories, autonomous systems will be able to operate with minimal human oversight, continuously optimizing processes based on real-time data.

Embrace the Future of Automation with TRLINK

Autonomous systems are transforming the way industries operate, providing businesses with the tools they need to improve efficiency, reduce costs, and enhance safety. By investing in autonomous systems today, businesses can position themselves for long-term success in an increasingly automated world.

If you’re ready to explore the potential of autonomous systems for your business, schedule a consultation with TRLINK. Our team of experts can help you implement cutting-edge automation solutions tailored to your specific needs.